海洋工程是一个包含机械,电气,软件和安全工程要素的领域,适用于帆船,油轮,潜艇和其他船舶。操作和生产成功的船只必须满足严格的性能和对安全性要求严格的标准。

您可能是船舶上使用的组件,零件或替换零件的供应商。在任何情况下,您的产品声誉取决于行业标准,内部规范和各个级别的客户期望。

我们来自船舶行业的客户将我们的测试解决方案用于各种质量控制测试应用程序,包括测试:

- 船用电缆的焊接和压接接头端子的抗拉强度

- 电连接器的插入/拔出力

- 铆接接头的抗拉强度

- 水下举升袋的抗张强度

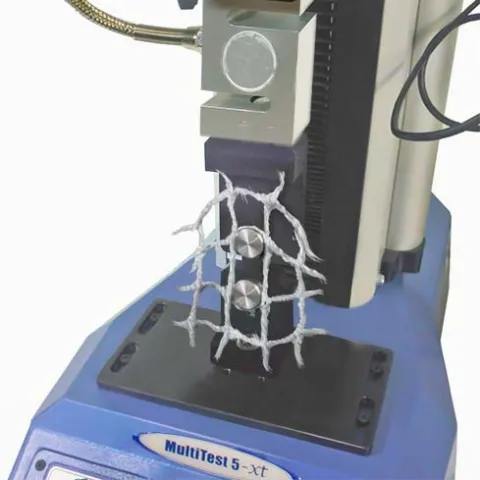

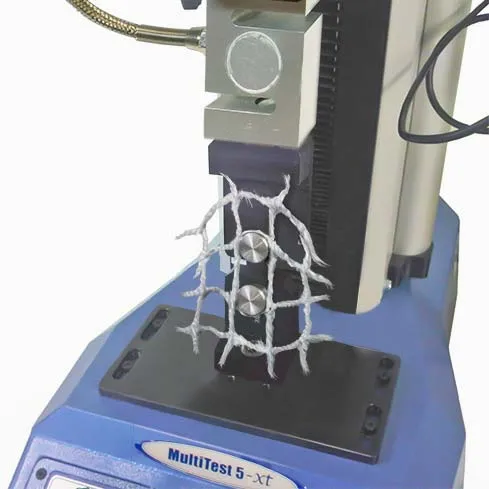

- 渔网的抗拉强度

- 应急信标,跟踪和监视设备上的开关驱动力

- 旋转控制件的扭矩

- 弹簧的压缩和拉伸特性

- 小型电动机的负载特性

- 紧固件的剪切强度和拉伸强度

- 船舶复合材料的剥离强度

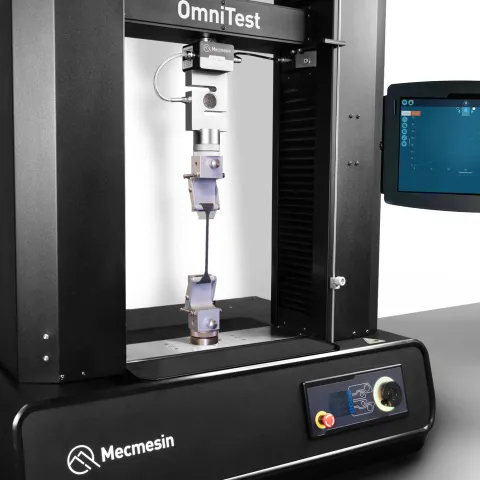

Mecmesin 的力学,材料和扭矩测试设备价格实惠,为您提供满足您的质量控制要求的多功能测试解决方案。我们为国防工业提供测试解决方案方面拥有40多年的经验。

Mecmesin 测试解决方案已在全球领先的制造商和工程公司中使用,无论是在组件,装配还是在完整制造级别。

根据ASTM,BS EN,ISO,DEF,DIN,CEN,MIL标准进行测试。

我们在运输行业也有丰富的测试专业经验。

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

Case study

钓线和绳结强度

Case study

渔网抗张强度测试,符合ISO1806

Case study

发动机燃油泵弹簧特性测量

Case study

电缆管道拔出力批量测试系统

Case study

橡胶垫片的拉伸试验

Case study