Search results

451

Event

Medical Devices – Syringe & Needle Testing Fundamentals

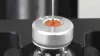

Vial sealing is a critical step in the process of ‘fill and finish’ operations for vaccines and medications, as it defines the seal quality of the final product, ensuring sterility and preventing leakage.

452

Case study

Insertion and withdrawal cyclic testing of aircraft audio connectors

Requirement

IFPL, based in the Isle of Wight, is a manufacturer of aircraft electronic interface components, bespoke audio and power products, plus turnkey solutions and services for their partners.

453

Case study

Syringe pump calibrator

Requirement

Medical device manufacturers, Cardinal Health, supply a range of syringe pump infusion systems to hospitals.

454

Case study

Dental abrasive disk integrity

Requirement

The resistance to slippage of the eyelet crimp at the centre of a dental abrasive disk is a key measure of the quality of the product.

455

Case study

Top-load Testing of Plant-based PLA Material Bottles

Requirement

BioPak Solutions in Roquefort-les-Pins, France, are leaders in the production of Polylactic Acid (PLA) bottles. The bottles are oil-free, contain no PET or Bisphenol A, and are made 100% from carbon-absorbing plants.

456

Case study

Torque testing closures on multi-way plastic bottles

Customised engineering example

A pharmaceuticals company wanted to test the closure torque of a series of square-profile PET bottles.

457

[Page extract]

SAE J 1907

This recommended practice defines a procedure for the construction and testing of a 180 deg peel specimen for the purpose of determining the bondability of glass to elastomeric material in automotive modular glass.

458

Case study

Police force manual handling and protective clothing

Requirement

A major UK police force requires all new recruits to pass a ‘Job Related Fitness Test’ (JRFT), to ensure they are able to meet the taxing physical demands of the role. Armed officers must undergo yearly re-assessment.

459

Event

Top-load testing: Ensuring packaging integrity from production to transport

Top-load testing is the method used to simulate and measure the force exerted on packaging containers during production, filling, capping, storage, and transport.

460

[Page extract]

ASTM C582

This specification covers composition, thickness, fabricating procedures, and physical property requirements for glass fiber reinforced thermoset polyester, vinyl ester, or other qualified thermosetting resin laminates comprising the materials of constr

461

Event

Tensile Testing for Wiring Harness Connections

The only way of really knowing the strength of a crimped terminal is to pull it. This can reveal production problems, where strand nicks, incorrect crimp height, or effects from changes in terminal supply, may not be clearly apparent.

462

Event

Medical Devices – Syringe & Needle Testing Fundamentals

Vial sealing is a critical step in the process of ‘fill and finish’ operations for vaccines and medications, as it defines the seal quality of the final product, ensuring sterility and preventing leakage.

463

[Page extract]

ASTM F1566-09

These test methods cover recognized methods for testing mattress innersprings, boxsprings, and finished mattresses or mattress sets, or both, to ensure uniformity of results.

464

Event

Fundamentals of Torque Testing

If you have ever struggled to open your favorite bottle of water or jam or required help loosening the lug nuts on your car’s wheels, it is likely due to a case of over-torque.

465

[Page extract]

ASTM D953-18

ASTM D953 is a test method that covers the determination of the pin-bearing strength of rigid plastics in either sheet form, molded form, or in reinforced thermoset form.

466

Case study

Electrical connector insertion and withdrawal forces

Customised engineering example

Push-fit electrical connectors with hole or dimple detents (also known as 'spade terminals') must offer a firm but practical fit.

467

Event

Tensile Testing for Wiring Harness Connections Webinar

The only way of really knowing the strength of a crimped terminal is to pull it.

468

[Page extract]

EN TS 15945

The purpose of DD CEN/TS 15945 is to specify test methods to evaluate the ease of opening of consumer packages, in order to improve easy access to the contents. For packages regulated for safety or similar reasons, e.g.

469

[Page extract]

MIL 22520-G

This specification covers the general requirements for crimping tools, accessories and inspection gages used for connecting removable contacts (such as; signal, power, coaxial, shielded, thermocouple, and filter pin contacts) coaxial connectors, shielde

470

Bundle

Top-load PET bottle CSD non-vented

OmniTest 2.5

BD

Top-load testing (also known as 'column-crush' and 'axial force resistance') is performed mainly on blow moulded, thermoformed or injection moulded plastic containers such as PET (Polyethylene terephthalate) bottles.

471

[Page extract]

Tools and equipment for shear testing

Accurate shear testing in tension requires high-quality, precise equipment:

472

Case study

Connection test on fuel injection components

Requirement

A number of destructive and non-destructive tests were required on a plastic assembly used in a fuel injection assembly. The tests included:

473

Event

Fundamentals of Torque Testing

If you have ever struggled to open your favorite bottle of water or jam or required help loosening the lug nuts on your car’s wheels, it is likely due to a case of over-torque.

474

Case study

Flat Quick-connect Termination

Requirement

A test system was needed to meet the requirements of test standard BS5057.

475

Case study

Electrical assembly component strength

Customised engineering example

Due to the complex, asymmetric shapes of electrical assemblies, it can be difficult to grip the soldered, fused and welded parts in a way that mimic the forces applied when in use.