The TTT-300 range features portable torque testers designed for measuring the click torque and maximum torque values of indicating and setting torque tools.

5 different models are available with capacities from 2 N.m to 50N.m making them ideal for quick and easy verification of torque wrenches, torque screwdrivers and motorised torque tools right at their point-of-use.

The TTT_Certify software is included as standard, enabling the tester to be used for the calibration of torque tools according to the requirements of ISO 6789.

Got a question about a product? Your local representative is...

Mecmesin/PPT Group, UK

Emperor™ Software

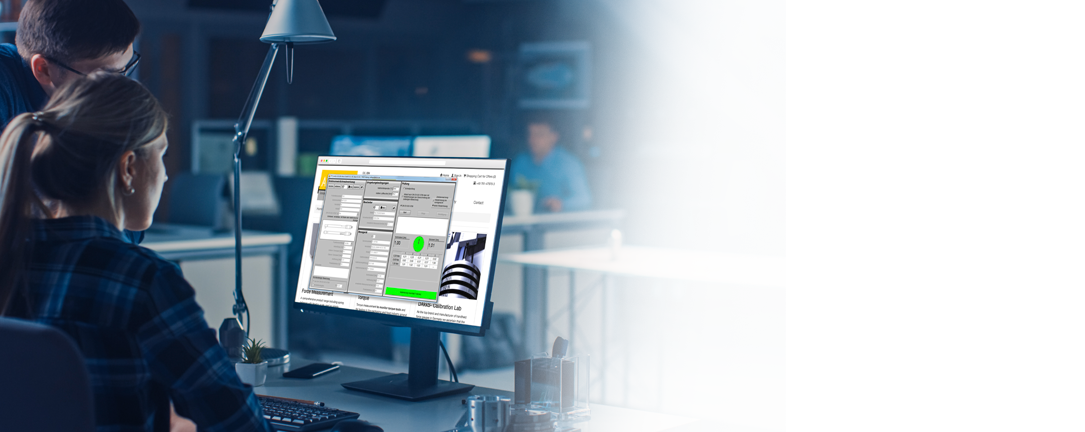

TTT_Certify software

Generate compliant torque calibration certificates

Included with the TTT-300 is our TTT_Certify software for generating calibration certificates, conforming to ISO 17025 standards for handheld, indicating and click torque tools, such as torque wrenches or torque screwdrivers.

Predefined calibration procedure for all classified types of tools acccording to ISO 6789:2003. Databased file system for administration tools, test equipment, operators and calibration certificates.

Generates PDF calibration certificates.

Software for generating calibration certificates, conforming to ISO 17025 standards for handheld, indicating and click torque tools, such as torque wrenches or torque screwdrivers.

Predefined calibration procedure for all classified types of tools acccording to ISO 6789:2003. Databased file system for administration tools, test equipment, operators and calibration certificates.

Generates PDF calibration certificates.

Overview

The TTT-300 range of Torque Tool Testers enables the verification of torque devices quickly and conveniently at their point-of-use, such as in the workshop or next to the production line. They can be used for checking manual wrenches & screwdrivers as well as electrically-powered torque tools.

5 models are available in the TT-300 range to cover the most common working capacities of hand torque tools: 0.2 - 2N.m, 0.5 - 5N.m, 1 - 10N.m, 2.5 - 25N.m and 5 - 50N.m

Each tester can be configured to display in one of 4 different modes:

Standard: displays the live torque reading in both clockwise (CW) and counter-clockwise (CCW)

Peak CCW: captures and displays the first 'click torque' peak and the second 'maximum torque' - in CCW only

Peak CW: captures and displays the first 'click torque' peak and the second 'maximum torque' - in CW only

Peak Actual: displays the currently applied torque whilst also capturing the maximum torque values in both CW and CCW

The Quick-Check function is particularly useful. It allows 5 consecutive measurements to be stored automatically and takes the average of the 5 peak readings. This can then be compared to assigned tolerance limits and the tester can indicate a pass/fail with LED status for instant classification for operators.

The TTT-300 features internal memory for storing torque readings and can clearly display the statistical information from all measurements. The USB interface allows the data to be exported to external applications, e.g. to SPC (Statistical Process Control) systems.

The TTT_Certify software is included as standard, enabling the tester to be used for the calibration of torque tools according to the requirements of ISO 6789 and to generate a calibration certificate for the tool in PDF format.

Ruggedly built for tough working environments; its steel case can be screwed to benchtops and the torque cell is overload-protected to minimise the risk of accidental damage.

The TTT-300 comes supplied with standard adapters to suit common torque tool heads. Run-down fixtures are also available for motor-driven torque tools up to 10N.m. A horizontal test stand for securing torque wrenches (TTT-920) and a vertical stand for fixing torque screwdrivers (TTT-921) can be added to complete the tester as a fully-comprehensive torque tool testing station.

Product datasheets

Product Brochures

Key specs

Capacity (f.s.) and measuring range

| TTT-300B2 | TTT-300B | TTT-300C1 | TTT-300C2 | TTT-300C5 | |

|---|---|---|---|---|---|

| N.m | 0.2 - 2 | 0.5 - 5 | 1 - 10 | 2.5 - 25 | 5 - 50 |

Resolution

| TTT-300B2 | TTT-300B | TTT-300C1 | TTT-300C2 | TTT-300C5 | |

|---|---|---|---|---|---|

| N.m | 0.002 | 0.005 | 0.05 | 0.02 | 0.05 |

Overload - maximum allowable without damage

| TTT-300B2 | TTT-300B | TTT-300C1 | TTT-300C2 | TTT-300C5 | |

|---|---|---|---|---|---|

| N.m | ± 20 Nm | ± 70 Nm | |||

Accuracy

±0.5% of full-scale (f.s) : Class 1 (DAkkS-DKD-R 3-8)

Acquisition rate

1000 times per second

Operating modes

Standard

Realtime values

Peak (Click + Peak 2)

First Click-torque and second peak (maximum)

Quick check

Five consecutive measurements with calculation of the arithmetic average

Limit

Separately selectable upper and lower tolerance limitsProtection

Rating

IP42 (Protected against dripping water)

Output

via USB 2.0 Interface

Dimensions mm (LxWxH)

280 x 147 x 79

Supplied with:

Standard: TTT300 Torque Tool Tester c/w 3/8" female socket, adapters for 3/8" and 1/4" male square, adapters for 5/16", 1/4" and 5/32" female hex, USB interface cable, CD-ROM with TTT_Certify software, quickstart operation manual. Optional: Operating instructions with CE declaration of conformity(printed), Dakks (German) calibration certificate, rundown fixture up to 10N.m, horizontal and vertical test stands, protective carry case - order separately as required.

Key applications

Got a question about a product? Your local representative is...