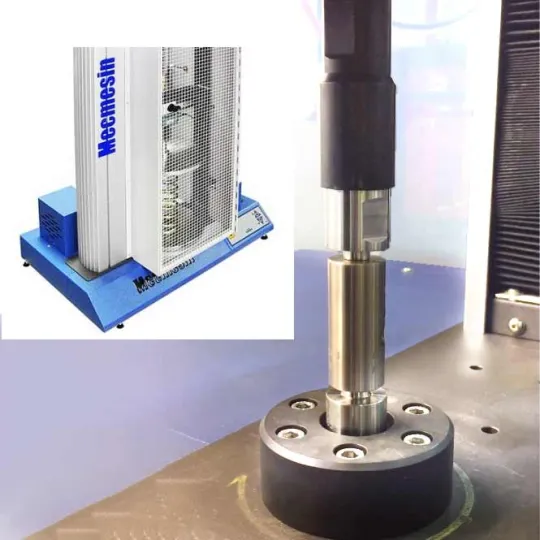

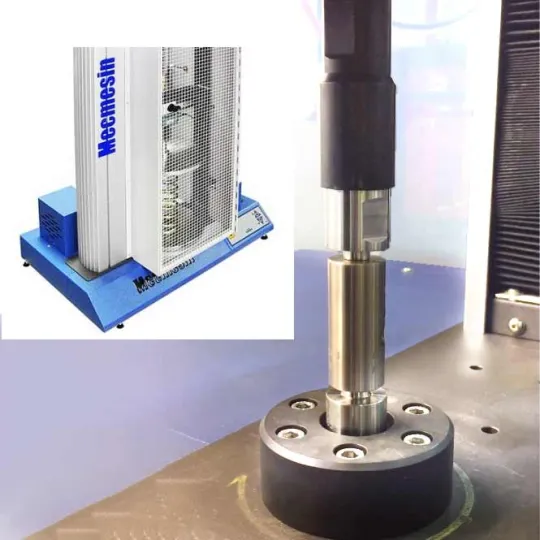

Testing fluid control valves and seals

Solution

- Tensile and compression force tester, single or twin-column

- Software to perform calculations, compare to pass criteria

- Appropriately rated loadcells

- Grips matched to spring dimensions

Benefits

- Optimum control and test repeatability

- Ability to test various designs with the same machine

Requirement

A typical gas lift system for oil and gas production requires a set of valves to operate along the production tubing down the drilling well. The valves open in sequence to inject the gas, which then lifts the fluid in the tubing to the surface. A valve will automatically open under a specific pressure, with the opening being operated by a bellows or through a spring-loaded mechanism. Valves must be engineered to perform dependably under a wide range of environmental conditions and in remote locations, so it is critical that they be tested for mechanical strength before being installed. Furthermore, valves needing attention or replacement are an integrated part of an entire tubing assembly; requiring a maintenance crew to remove it from a well.

Other applications for valves include spring-operated safety and pressure relief valves, which must meet the demanding requirements of oil and gas producers, refiners, power generators and the processing industry in order to more effectively control their liquid, steam or gas operations.

As long pipelines require compressors along the way to keep the product moving and valves are needed to protect equipment while offering minimal restrictions to the flow, the performance of the centrifugal compressor is equally important. Testing the floating ring seals for their compressive characteristics is essential. Dry gas seals accomplish effective sealing by virtue of a stationary and a rotating disc having a very small gap (about 5 µm) between them and, at standstill, springs pressing the movable seal disc onto the stationary disc. It is this spring force which is measured to ensure it lies within acceptable tolerances.

Solution

Mecmesin force testing systems are used extensively to check the tension and compression force characteristics for actuation of valves and other spring assemblies. A range of bench-top test frames from 2.5kN up to 50kN cover the most common loads applied whilst the test software is fully configurable to compress a valve to a known displacement or load over a single-cycle or a series of multiple cycles. Data can be presented in graphical format with a calculated results table indicating a pass or fail of the component against its quality criteria.

Extended crossheads, guards, custom fixtures to securely seat the spring and ensure correct axial compression, are all able to be integrated in the solution.

Specific Mecmesin customer applications have included:

- Push-fit plastic valves used in water supply for both commercial (water treatment plants) and non-commercial (swimming pools, etc.); MultiTest 2.5-i

- PRV and PORV products for safety, high-pressure and back pressure relief implementations; testing of the springs; MultiTest 2.5-i

- Pressure-reducing and RPZ valve springs for heating and plumbing flow control in domestic systems; MultiTest 2.5-I and MultiTest 25-i

- Large spring assemblies used in oil and gas industry centrifugal compressors; MultiTest 2.5-i

- Cyclic actuation testing of flow control valves used in oil and gas applications; MultiTest 50-i

- Testing floating rim seals and testing springs on compressor components used for air separation in plants on industrial gas complexes; MultiTest 2.5-i

Test equipment

- Software controlled single or twin-column test stand

- Intelligent loadcells rated to the expected loads

- Fixtures appropriate to the test specimen geometry and characteristics