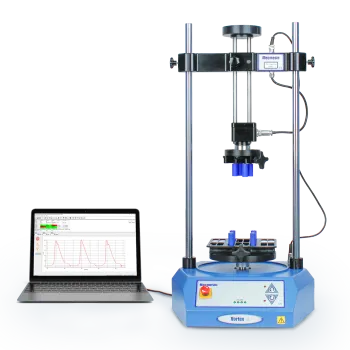

The Vortex-i is a top of the range torque tester controlled by software running on a PC. Accurate, easy to use and optimised for measuring static torque up to 10 N.m.

The ultimate flexible solution for automated torque testing of a wide range of closures and components.

The Vortex-xt is a multi-functional torque tester controlled by a touch-screen console. Rated up to 10 N.m it is accurate, easy to use and ideal for standalone use.

Its versatility as an automated torque tester makes it the perfect solution for routine testing of a wide range of closures and components.

The Vortex-i is a top of the range torque tester controlled by software running on a PC. Accurate, easy to use and optimised for measuring static torque up to 10 N.m.

The ultimate flexible solution for automated torque testing of a wide range of closures and components.

Got a question about a product? Your local representative is...

Mecmesin/PPT Group, UK

Vortex test frame

A sturdy twin-column test frame capable of applying torque up to 10 N.m (90 lbf.in). Tall and wide enough to accept a variety of test specimens yet compact to use as a bench-top tester.

Test frame

The Vortex-i and Vortex-xt have a sturdy, twin-column, motorised test frame which is designed to apply torque up to a capacity of 10 N.m.

Specimens up to 440mm tall and 280mm wide can easily be tested in both clockwise and counter-clockwise directions.

Connect your computer

The Vortex-i requires a Windows PC to run the Emperor software and control the torque tester. Its small footprint makes it the perfect choice as a bench-top device.

Integrated console

The Vortex-xt is fitted with a Windows-based touch screen console. Comparable to a standard PC but operates excellently as a standalone bench-top torque tester. It saves time by not having to move to and fro a computer.

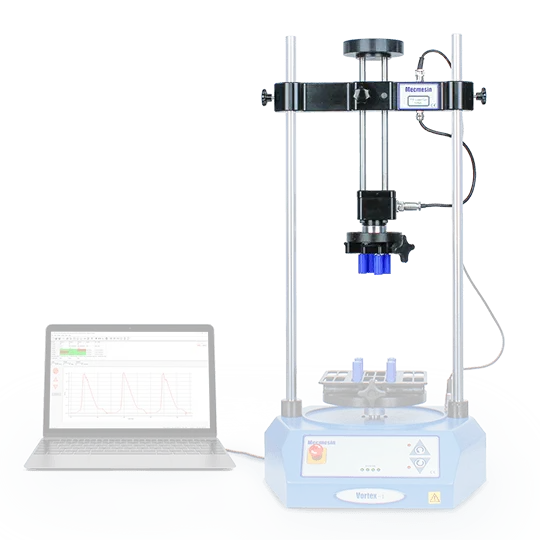

Torque sensors (ITC)

The ITC range of interchangeable torque sensors is specially adapted for the Vortex-i and -xt test systems. Plug and play for automatic calibration and available in 5 different capacities for all requirements, from 0 - 0.3 N.m (0 - 2.7 lbf.in) to 0 - 10 N.m ( 0 - 90 lbf.in).

ITC torque sensors

The ITC range of interchangeable torque sensors is specially adapted to the Vortex-i and -xt test systems.

They plug into the frame and their calibration characteristics are immediately recognised by the software of the tester without any input from the operator.

Each sensor is fitted with a ⅜" male square drive for connection to a range of fixing tables and chucks to hold your specimens.

To ensure that you have the optimum selection to meet all your torque testing needs, five different interchangeable sensors are available. All sensors measure from zero up to their nominal capacity allowing you to use the Vortex for low torque measurements up to 0.3 N.m and right up to 10 N.m.

Sensor capacity, range and accuracy

Each sensor reads from zero to its full nominal capacity (listed below). Measurement accuracy is an outstanding ±0.5% of the sensor capacity.

| Model | 0.3 N.m | 1.5 N.m | 3 N.m | 6 N.m | 10 N.m |

|---|---|---|---|---|---|

| N.m | 0 - 0.3 | 0 - 1.5 | 0 - 3.0 | 0 - 6 | 0 - 10 |

| kgf.cm | 0 - 3 | 0 - 15 | 0 - 30 | 0 - 60 | 0 - 100 |

| lbf.in | 0 - 2.7 | 0 - 13 | 0 - 26 | 0 - 52 | 0 - 90 |

Each sensor is delivered as standard with its own calibration certificate traceable to national standards.

Servicing and calibration

Mecmesin also provides annual servicing and torque sensor re-calibration. Talk to one of our engineers or your local national distributor to find out more.

Emperor™ Software

Emperor™ Torque software

Easy-to-use software with almost limitless freedom to design and customise torque tests to suit your needs. Developed by Mecmesin in close collaboration with our customers, Emperor™ is now trusted by over 5,000 companies for the detailed testing and evaluation of their products.

Create simple tests for the production line and more complex laboratory tests to prove design standards are met.

Key features

Create

Intuitive user interface

Build test routines step by step

Favourite one-touch tests

Test

Real-time graph plotting

Display measured and calculated values

Clear pass/fail indication

Report

Standard and customisable templates

Print results to Adobe PDF format

Export results to Excel and SPC packages

Trusted by over 5,000 customers worldwide

Learn more about EmperorAccessories

Choosing your accessories

It's important that your sample is gripped and held correctly to achieve accurate test results.

Our accessory catalogue contains a wide range of accessories and you should find exactly what you need. Key specifications (such as load rating) are listed on all of our grips and fixtures.

Example test accessoriesOverview

The Vortex-i and Vortex-xt automated torque testers have been helping professionals around the world to objectively assess the quality of their components and assembled products for more than 20 years.

They have become the accepted testers in industries as diverse as food and drink, pharmaceutical, cosmetics, and automotive.

They are ideally suited to a packaging manufacturer wishing to assess the bridge torque of a tamper-evident closure right through to an automotive controls designer looking to perfect the ‘feel’ of a rotary switch.

The motorised Vortex-i is controlled by software run on a computer and the Vortex-xt uses a touchscreen console to host the software. They deliver both consistency and reliability by controlling the key test parameters of torque, angle and speed. This means that the inherent variability found when using a manual torque tester is almost fully removed.

The automated Vortex-i and Vortex-xt testing systems each comprise four key elements:

Test frame

The Vortex-i and Vortex-xt feature a sturdy, twin-column, motorised test frame which is designed to apply torque up to a capacity of

Specimens up to 440mm tall and 280mm wide can easily be tested in both clockwise and counter-clockwise directions.

It requires a PC or touchscreen console to run it's software and has a small footprint making it the ideal choice as a bench-top device.

Torque sensors

The ITC range of interchangeable torque sensors is specially adapted to the Vortex-i and -xt. They plug into the frame and their calibration characteristics are immediately recognised by the tester without any input from the operator.

Five different sensors are available with nominal capacities ranging from

Each sensor is delivered as standard with its own calibration certificate traceable to national standards.

Software

Emperor software is at the heart of the Vortex-i and -xt test systems. It runs on any Windows computer and controls the motor of the test frame whilst collecting data at an impressive 1,000 Hz from the ITC torque sensor and angle encoder of the frame.

Step-by-step test routines can be quickly and easily created according to the exact requirements of your testing procedures. The most commonly used test routines can then be simply selected by the operator using their 'favourites' button or from a standard drop-down list.

By plotting measurement data in real-time on a graph the operator can identify exactly how the test specimen is performing. Preset calculations are used to analyse the data to determine whether the specimen has met the pass/fail criteria of the quality-control specifications.

At the end of the test, the powerful reporting module within Emperor™ allows the operator to issue a test report as a PDF. Additionally, the data can be exported to Excel or to the network for further analysis by a Statistical Process Control (SPC) package.

Gripping fixtures

Holding your test specimen in place without it slipping is essential to obtaining repeatable results. Mecmesin has designed a range of torque grips to hold a variety of components. They include chucks and mandrels to hold plastic and metal closures, fixing tables to secure bottles and containers plus many more.

The varying nature of specimen sizes and shapes often makes it necessary to design and produce a special grip. Mecmesin's team of design engineers can work with you to develop the best grip for your specimen. These are then produced on our 3D printers to create lightweight, precision fixtures or, for higher load applications, they are made from metal at our machine-shop.

Product datasheets

Product Brochures

Key specs

Torque

Sensors available (all measure from zero to the value indicated in the table below)

| Model ITC | 0.3 | 1.5 | 3 | 6 | 10 |

|---|---|---|---|---|---|

| N.m | 0.3 | 1.5 | 3 | 6 | 10 |

| kgf.cm | 3 | 15 | 30 | 60 | 100 |

| lbf.in | 2.7 | 13 | 26 | 50 | 90 |

Accuracy

±0.5% of full scale (~ sensor capacity)

Resolution

1:6500

Units of measurement

mN.m, N.cm, N.m, kgf.cm, gf.cm, ozf.in, lbf.in, lbf.ft

Sampling rate

2000 Hz

Data-acquisition rate

1000 Hz, 500 Hz, 100 Hz, 50 Hz, 10 Hz (user selectable)

Angle

Maximum displacement

2,440 revs

Accuracy

±0.2° per 36,000°

Resolution

0.2° (0.001 revs)

Speed

Range

0.1 - 20 rev/min

Accuracy

±1% of indicated speed

Resolution

0.1 rev/min

Dimensions

Maximum headroom

505 mm (19.9") without mounting tables

448 mm (17.6") with mounting tables fitted

Maximum travel of adjustable carriage

182 mm (7.2")

Width between columns

280 mm (11.02")

Opening span of lower mounting table

10 - 190 mm (0.39 - 7.5")

Opening span of upper mounting table

10 - 78 mm (0.39 - 3.07")

Weight

19.5 kg (43 lb)

Common specifications

Maximum power requirements

100 W

Voltage

230 V AC 50 Hz or 110 V AC 60 hz

Operating temperature

10 - 35°C (50 - 95°F)

Humidity range

Normal industry and laboratory conditions

Compensation for system movement

Yes

Loadholding

Yes

Graphical presentation

Yes

Output of test results to PC/printer/datalogger

Yes - Includes auto-export to Microsoft Excel. Also data-export via RS232 port (direct or via USB/Network converter in ASCII format)

Communication with PLC/digital control interface

Yes - Via programmable digital ports, 6 inputs and 6 outputs

Key applications

Got a question about a product? Your local representative is...