Search results

Soluções Mecmesin para engenharia e design de transporte.

A engenharia de transporte envolve uma complexidade enorme, combinada com os recursos mais críticos para a segurança.

Seja você um fornecedor de componentes, submontagens ou peças de reposição ou um fabricante de uma marca OEM, sua reputação dependerá da conformidade com os padrões do setor, especificações internas e expectativas dos clientes em todos os níveis.

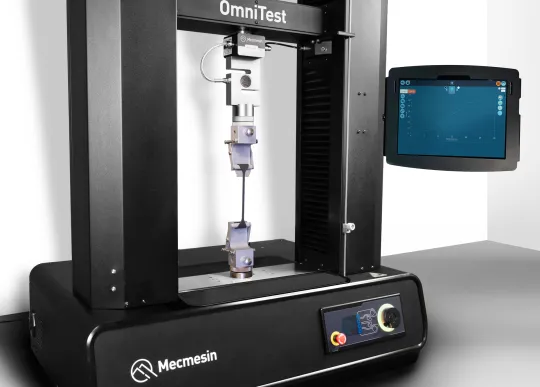

Medições rápidas e precisas com equipamentos confiáveis de teste de força e torque são uma parte essencial do controle da qualidade de seus produtos e da garantia total de segurança e percepção da marca.

Os sistemas e instrumentos da Mecmesin são utilizados internacionalmente pelos principais fabricantes e empresas de engenharia, nos níveis de componentes, montagem e construção completa.

Teste para ASTM, BS EN, ISO, DEF, DIN, CEN, MIL, VDI

Esse setor industrial concentra-se em nossas soluções para fabricantes de trens, bondes, trollies e modos de transporte similares. A Mecmesin testa a carroceria, o chassi e os componentes e subsistemas elétricos desses veículos de transporte em geral quanto aos requisitos exclusivos de funcionalidade.

Também temos uma vasta experiência nos importantes setores relacionados a indústria aeroespacial , automotiva e marítima .

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

Train door closing pinch force tester

Motorcycle switchgear actuation forces

Teste de molas de vagões

Teste de tração em juntas de borracha

Estação de teste de filtro

Teste de terminal de chicote elétrico

![Força de fechamento da porta [PDV11019] Força de fechamento da porta [PDV11019]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2020-12/1714-PDV11019.jpg.webp?itok=k9xdm3ae)