Search results

Soluções Mecmesin para o setor de alimentos e bebidas.

Vivemos em um mundo onde a maioria dos alimentos e bebidas são fornecidos pré-embalados em embalagens que protegem, mas que foram projetadas para serem abertas com facilidade.

A enorme quantidade de embalagens de uso único e o crescimento das regulamentações ambientais criam pressão para produzi-las com o mínimo de desperdício e despesas, ao mesmo tempo em que garantem que sejam adequadas ao seu objetivo. É aí que os testes físicos das embalagens de alimentos e bebidas se tornam essenciais para garantir que a experiência do cliente seja positiva:

- As embalagens de alimentos do consumidor precisam ser descascadas e abertas, portanto, devem ser projetadas e verificadas quanto à vedação máxima e descascamento mínimo.

- As bolsas de retorta exigem que o consumidor supere uma perfuração pré-rasgo, enquanto suporta as forças de perfuração para proteger o conteúdo.

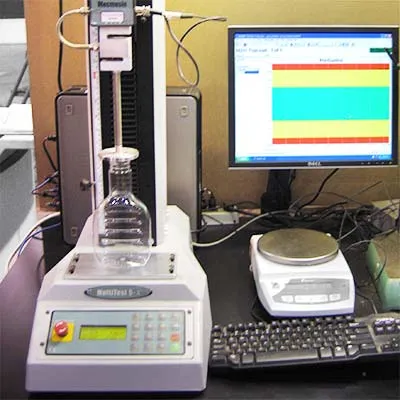

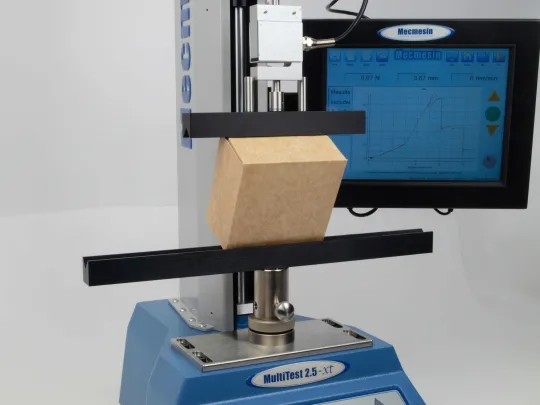

- Garrafas de bebidas de plástico precisam usar uma quantidade mínima de matéria-prima e ainda assim suportar as forças aplicadas durante o enchimento e o empilhamento, para que precisem ser testadas quanto à resistência à carga máxima.

- Torcer a abertura de um tampão ou fechamento de bebidas pode ser um desafio, especialmente para os idosos. Os testes de torque durante o ciclo de design e produção tornam-se críticos para garantir a usabilidade e para que a imagem da marca não seja prejudicada por embalagens ruins.

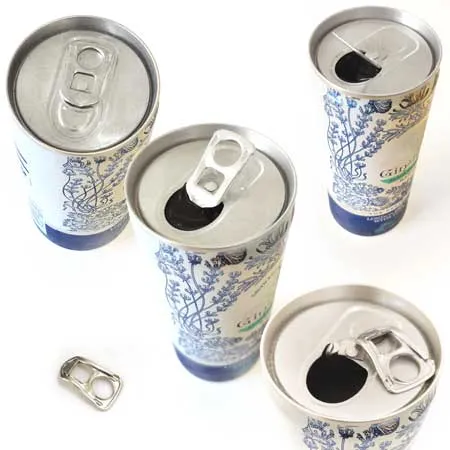

- As latas de spray requerem a pressão correta dos dedos para ativar o aerossol. Os puxadores de anel devem fornecer uma vedação segura, mas não exigem força de abertura excessiva que quebre as unhas ou corte os dedos.

A lista de aplicações é quase infinita e quanto mais a embalagem se torna estética, mais difícil pode ser a aderência e o teste.

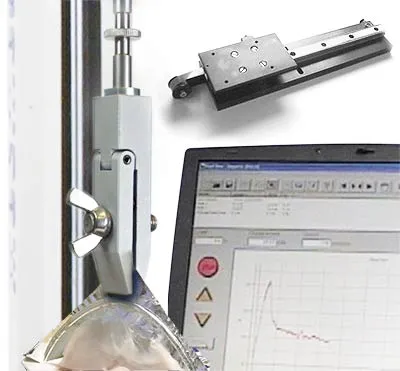

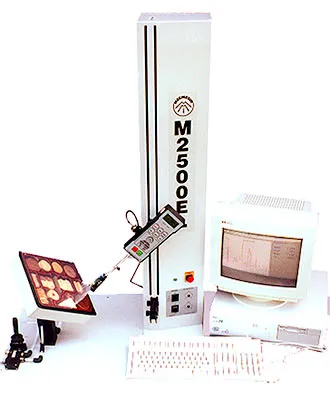

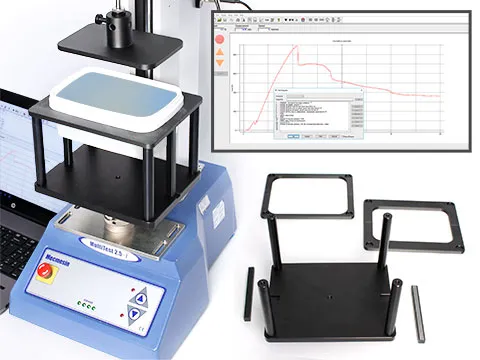

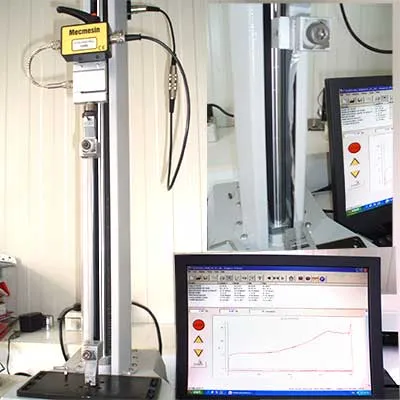

Na Mecmesin, projetamos sistemas e acessórios de medição de força e torque para testar todos os tipos de produtos de embalagem, para que você possa aplicar métodos de teste padrão do setor em projetos e no chão de produção para controle de qualidade.

Nosso software de controle e análise Emperor é poderoso e flexível para testes confiáveis, precisos e repetíveis com o pressionar de um botão.

Teste de acordo com os padrões da sua empresa, bem como com ASTM, BS EN, ISO, DIN, CEN, Afera, FEFCO, FINAT, PSTC, TAPPI e TLMI

Se você precisar de uma solução para análise de textura dos próprios alimentos, visite nossa empresa irmã Food Technology Corporation (FTC) , que tem mais de 40 anos de experiência no design e fabricação de analisadores de textura, prensas de textura e tenderômetros.

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

Tethered closures testing attachment force

Teste de adesivo em rolhas encapsuladas

Mandris de tampa de garrafa personalizados

Tampas de líquido a granel

Integridade do saquinho de chá

Sistema Rotativo de Peeling a Vácuo

Teste de rotação de boné esportivo ISBT

Fast food tray crush testing

Top-load testing PET bottles

Top-load crush test of plastic bottles

Teste de penetração de torta de porco

Teste de tração em filme de polietileno

Teste de toque com evidência de violação

Teste de extração de rolhas de uísque

Teste de compressão de sachê

Teste de tensão de fechamento esportivo ISBT

Torque para torcer uma rolha de champanhe

Simulate interactions with food, cosmetics and pharmaceuticals

Through texture analysis you can simulate any interaction with food, cosmetics or pharmaceutical products and measure the physical sensory experience.

This enables you to control production, ensure quality and optimise processing.

Discover more about texture analysis on our specialist application microsite - TextureAnalyzers.com.

![Teste de dobra da caixa de fixação de sucção, posição totalmente aberta [PDV8017] Teste de dobra da caixa de fixação de sucção, posição totalmente aberta [PDV8017]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2020-12/989-cardboard-beverage-tension-test-system.jpg.webp?itok=v-xgxcIO)

![Colares de válvula press-fit [PDV14192] Colares de válvula press-fit [PDV14192]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2020-12/1650-PDV14192-1-web.jpg.webp?itok=5HrBrRab)