Glued cardboard packaging integrity

Solution

- Software-controlled test stand

- Bespoke pneumatic vacuum fixture

Benefits

- 40% calculated cost savings

- Semi-automatic repeatable test procedure

- Helped to optimise several upstream processes

Companies show their worth when presented with a unique problem to solve. Be assured, I will have no hesitation in recommending Mecmesin to friends and business colleagues.

Dale Baker, CI Manager

Graphic Packaging International, UK

Requirement

Graphic Packaging International is a leading designer and manufacturer of food and beverage packaging. The company needed to perform integrity checks on beverage basket carriers and cardboard box packaging to optimise production line efficiency and maintain consistent standards of packaging quality.

Constructed from multiple pieces of card, which are glued together, the packaging is initially manufactured flat and opened out to accommodate the end product whilst moving along the production line. A tensile test could ascertain whether processes were optimised to enable the glue to set in time for the next stage of production to begin. It could also ensure the correct application of glue on the tabs, to minimise the risk of packages sticking together, preventing them from opening out when required.

Solution

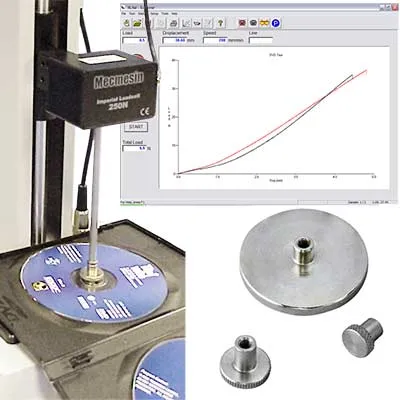

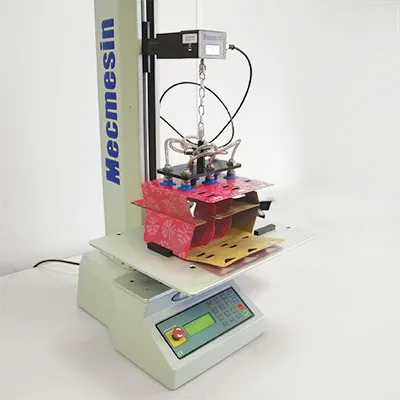

This application required a bespoke solution to be designed and manufactured. Together with Graphic Packaging International, Mecmesin created a vacuum fixture, which mimicked the actions of the end-users application. The vacuum fixture uses suction to hold onto the flat packed basked carrier, which is clamped into position on the specially manufacture base plate. Using a MultiTest-x (semi-automatic) test system, the top of the basket carrier is raised at a speed of 500 mm/min, opening out the packaging to a maximum load of 11N in order to determine its integrity.

Prior to purchasing a Mecmesin test system, Graphic Packaging had performed this test by hand assessment only. Since the introduction of the system, the company had been able to reduce costs by 40%.

Test equipment

- MultiTest 1-x Test Stand with Special Base Plate Fixturing (The MultiTest 1-x has been superseded by the MultiTest 1-xt)

- XLC Loadcell 100 N

- Bespoke Vacuum Fixture