Search results

Les entreprises scientifiques et technologiques agissent souvent comme une interface entre les entreprises et les centres de connaissances tels que les universités, les laboratoires financés par le gouvernement et, dans certains cas, les laboratoires d’entreprise. Il existe une demande croissante pour aider à commercialiser des idées innovantes issues de la recherche, tout en respectant des contraintes budgétaires difficiles.

Combiner le savoir-faire en matière d'invention avec la résolution de problèmes est un défi courant. Le choix des matériaux et des processus adéquats est donc essentiel pour une innovation rentable.

Une compréhension approfondie des matériaux et de leurs propriétés lors de leur mise en œuvre dans de nouvelles conceptions et de nouveaux processus peut faire toute la différence dans la course au succès dans un environnement concurrentiel mondial.

Pour obtenir des performances améliorées et en prouver le caractère non seulement en tant que prototype, mais également de manière durable sur une base commerciale, le produit doit souvent être testé pour ses caractéristiques de contrainte-déformation, de traction, de ténacité et de rupture, dans des domaines aussi divers que:

- Génie biomédical

- Technologie automobile

- Nano Technologie

- Ingénierie du sport

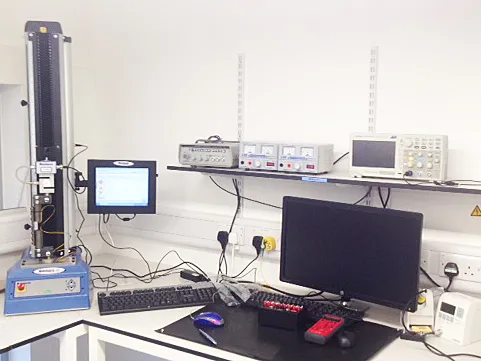

Les bancs d'essai Mecmesin de force, de couple et de matériaux sont utilisés par des sociétés scientifiques et technologiques du monde entier.

Mecmesin peut vous aider, que vous installiez un nouveau laboratoire et que vous ayez besoin d'un banc d'essai ou que vous meniez des recherches sur de nouveaux matériaux. Jetez un coup d'œil à certaines applications typiques de nos clients et contactez-nous pour savoir comment nous pouvons vous proposer une solution de test abordable.

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

Testing rubber to materials standards

Tests de mesure de force sur dispositif médical

Force de morsure et de fracture

Force d'actionnement de l'écran tactile