Plastic styled motor fluid container land surface seal adhesive peel

Solution

- Software-controlled test stand

- Custom fixtures to hold a range of containers

Benefits

- Secure location of different container shapes and sizes

- Repeatable testing in-house to meet safety and usability criteria

Requirement

Bullsone is Korea’s leading manufacturer of auto care products. They offer a wide range of cleaning and preserving products for components used in vehicle exterior and interior body trim. Bullsone has a strong commitment to the environment, and its products support green technology initiatives. The company uses several designs of container, appropriate to the customer requirement, in association with closures for purely sealing and also dispensing the contents.

The automotive industry imposes strict legislation with regard to products with potentially harmful chemical ingredients, therefore Bullsone must ensure the closure sealing must be effective against both leakage and resist access by children. Several products are fitted with an internal aluminium foil induction seal across the container finish, which must be peeled from this land surface to initially open the pouring orifice.

Solution

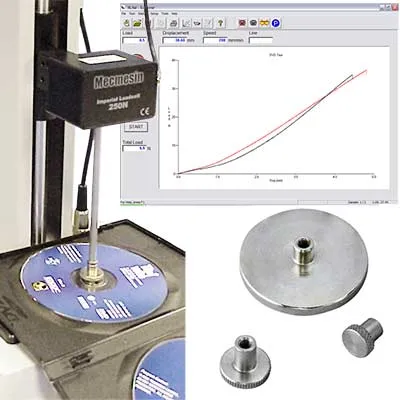

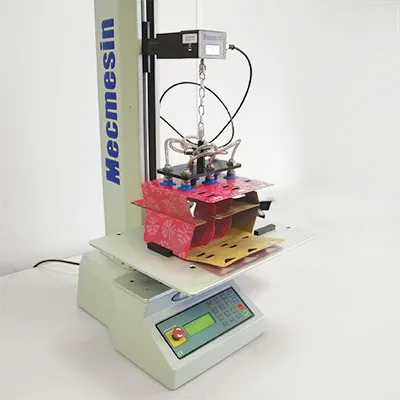

Mecmesin Korea designed an adjustable fixture to locate a variety of container designs, aligned correctly with an upper pinch grip attached to the UTM crosshead. An aperture enables the seal to be gripped and pulled upwards without hindrance. The computer-controlled MultiTest test system was then programmed to peel the inner lip seal at 90 degrees at a constant speed to guarantee optimum repeatability.

Measurement of the peel quality is determined by the number of load peaks and their maximum force values, which enables the manufacturer to quantify the adhesion characteristics, content security and ease-of-opening performance.

Test equipment

- MultiTest 2.5-i Universal tester and intelligent loadcell

- Small pinch grip to hold the seal

- Custom-made fixture to hold the lower container

- EmperorTM software